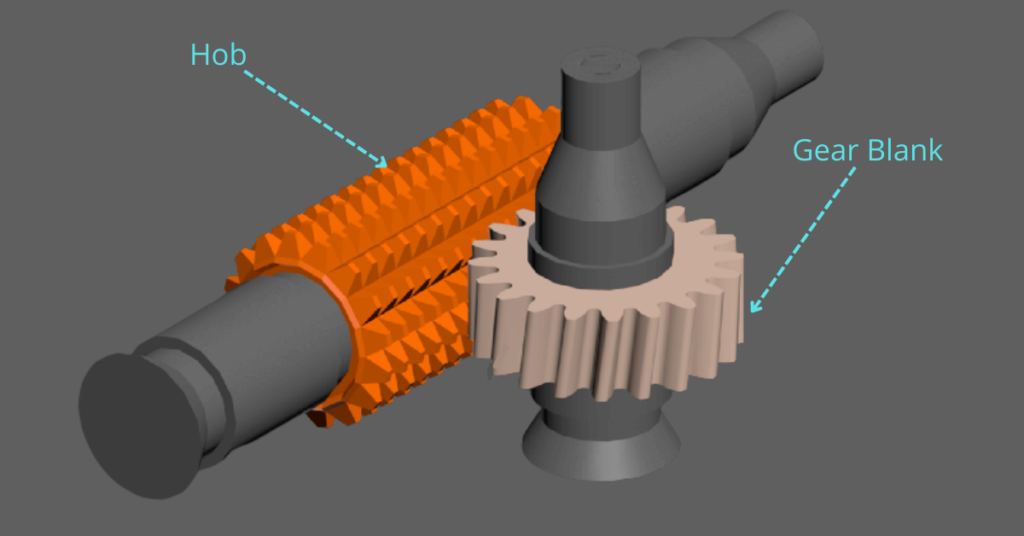

Cnc Lathe Gear Hobbing . gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. with this technology, it became possible for the first time to produce. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. The gear hobbing unit offers high stiffness and runout accuracy. in principle, turning and hobbing require two different machines. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. high productive manufacturing of gears with cnc turning centers. gear hobbing is a machining process used to cut gears, splines, and sprockets.

from www.motorgearengineer.com

We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. The gear hobbing unit offers high stiffness and runout accuracy. in principle, turning and hobbing require two different machines. gear hobbing is a machining process used to cut gears, splines, and sprockets. with this technology, it became possible for the first time to produce. high productive manufacturing of gears with cnc turning centers. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs.

Gear Hobbing Service Introduction, Working, and Applications

Cnc Lathe Gear Hobbing we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. The gear hobbing unit offers high stiffness and runout accuracy. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. gear hobbing is a machining process used to cut gears, splines, and sprockets. with this technology, it became possible for the first time to produce. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. in principle, turning and hobbing require two different machines. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. high productive manufacturing of gears with cnc turning centers.

From www.youtube.com

Gear Hobbing on Lathe Polygon Turning YouTube Cnc Lathe Gear Hobbing high productive manufacturing of gears with cnc turning centers. gear hobbing is a machining process used to cut gears, splines, and sprockets. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. It involves using a specialized cutting tool known as a hob, which rotates. Cnc Lathe Gear Hobbing.

From geepro.en.made-in-china.com

China Vertical/Horizontal Gear Hobbing CNC Lathe Machine for Shaft Cnc Lathe Gear Hobbing with this technology, it became possible for the first time to produce. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. gear. Cnc Lathe Gear Hobbing.

From www.indiamart.com

Premier PHA 250 250 Mm 3 Axes CNC Gear Hobbing Machine at best price in Cnc Lathe Gear Hobbing The gear hobbing unit offers high stiffness and runout accuracy. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. with this technology, it became possible for the first time to produce.. Cnc Lathe Gear Hobbing.

From geepro.en.made-in-china.com

Stock 6axis CNC Vertical Gear Hobbing Machine for 14 Module 200mm Dia Cnc Lathe Gear Hobbing It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. The gear hobbing unit offers high stiffness and runout accuracy. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. gear hobbing is a. Cnc Lathe Gear Hobbing.

From njwgmachine.en.made-in-china.com

Custom OEM CNC Axis Machine Lathe Gear Gear Hobbing Cutters China Cnc Lathe Gear Hobbing It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. gear machining on a cnc lathe through hobbing requires. Cnc Lathe Gear Hobbing.

From www.youtube.com

CNC Gear Hobbing Machine EIFCO YouTube Cnc Lathe Gear Hobbing high productive manufacturing of gears with cnc turning centers. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. The gear hobbing unit offers high stiffness and runout accuracy. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to. Cnc Lathe Gear Hobbing.

From www.youtube.com

Liebherr Gear Hobbing Machine LC 380500 YouTube Cnc Lathe Gear Hobbing in principle, turning and hobbing require two different machines. high productive manufacturing of gears with cnc turning centers. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time. Cnc Lathe Gear Hobbing.

From vertexgearmachines.com

CNC Gear Hobbing Pfauter PE 150 Used Gear Machines Provider Cnc Lathe Gear Hobbing gear hobbing is a machining process used to cut gears, splines, and sprockets. The gear hobbing unit offers high stiffness and runout accuracy. with this technology, it became possible for the first time to produce. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs.. Cnc Lathe Gear Hobbing.

From www.indiamart.com

Liebherr LC 122 CNC Gear Hobbing Machine, CNC Gear Hobbing Machinery Cnc Lathe Gear Hobbing gear hobbing is a machining process used to cut gears, splines, and sprockets. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. in principle, turning and hobbing require two different machines. The gear hobbing unit offers high stiffness and runout accuracy. with this technology, it became possible for. Cnc Lathe Gear Hobbing.

From www.alibaba.com

Yk3180 Vertical Cnc Gear Hobbing Machine For Sale Buy Gear Hobbing Cnc Lathe Gear Hobbing gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. in principle, turning and hobbing require two different machines. high productive manufacturing of gears with cnc turning centers. with this technology, it became possible for the first time to produce. The gear hobbing unit offers high stiffness and runout. Cnc Lathe Gear Hobbing.

From www.jskingston.com

Kingston Brand CNC Gear Hobbing Machine YK31125CNC 6 Axis Cnc Lathe Gear Hobbing gear hobbing is a machining process used to cut gears, splines, and sprockets. with this technology, it became possible for the first time to produce. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. The gear hobbing unit offers high stiffness and runout accuracy.. Cnc Lathe Gear Hobbing.

From boruigearmachine.com

CNC gear hobbing machine hob selection BORUI Gear Machine Cnc Lathe Gear Hobbing We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. with this technology, it became possible for the first time to produce. we would like to welcome helical gear hobbing in. Cnc Lathe Gear Hobbing.

From www.pli-international.com

CNC Gear Hobbing Machine LIEBHERR LC802 PLI International Cnc Lathe Gear Hobbing high productive manufacturing of gears with cnc turning centers. We present a new application on helical gear hobbing that shows teeth being machined directly in the cnc lathe. in principle, turning and hobbing require two different machines. we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time. Cnc Lathe Gear Hobbing.

From www.youtube.com

Gear Hobbing A Spline on a LiveTool Lathe YouTube Cnc Lathe Gear Hobbing It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. high productive manufacturing of gears with cnc turning centers. gear hobbing is a machining process used to cut gears, splines, and sprockets. with this technology, it became possible for the. Cnc Lathe Gear Hobbing.

From geepro.en.made-in-china.com

China Vertical/Horizontal Gear Hobbing CNC Lathe Machine for Shaft Cnc Lathe Gear Hobbing we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. with this technology, it became possible for the first time to produce. The gear hobbing unit offers high stiffness and runout accuracy. gear hobbing is a machining process used to cut gears, splines, and sprockets.. Cnc Lathe Gear Hobbing.

From www.exportersindia.com

Cnc Gear Hobbing Machine at Best Price in Coimbatore ID 4042718 Cnc Lathe Gear Hobbing we would like to welcome helical gear hobbing in a cnc lathe and say goodbye 👋 to the dead time that occurs. high productive manufacturing of gears with cnc turning centers. with this technology, it became possible for the first time to produce. The gear hobbing unit offers high stiffness and runout accuracy. gear hobbing is. Cnc Lathe Gear Hobbing.

From www.emag.com

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level Cnc Lathe Gear Hobbing high productive manufacturing of gears with cnc turning centers. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. with this technology, it became possible for the first time to produce. The gear hobbing unit offers high stiffness and runout accuracy.. Cnc Lathe Gear Hobbing.

From www.pinterest.com

Gear Hobbing Gears, Metal lathe tools, Mechanical design Cnc Lathe Gear Hobbing gear hobbing is a machining process used to cut gears, splines, and sprockets. gear machining on a cnc lathe through hobbing requires a special live toolholder to mount the hob. high productive manufacturing of gears with cnc turning centers. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into. Cnc Lathe Gear Hobbing.